In a recent research it is found that, there are three major causes of pump line blockage. These are: problem in mixture, problem in pipeline itself, and mistake made by human as an operator or any other.

Let’s focus on these three issues:

Cause #1:

The Improper Mixing of Cement, Aggregate and Water

It is the most common problem of the pipeline. The final concrete does not contain the proper amount of water and cement. Due to the improper mixing, segregation like situation occurs. Concrete must be poured within a fix time period when mixing gets completed. Otherwise you will face problem in installation. Concrete will not come out properly from pipeline.

Cause #2:

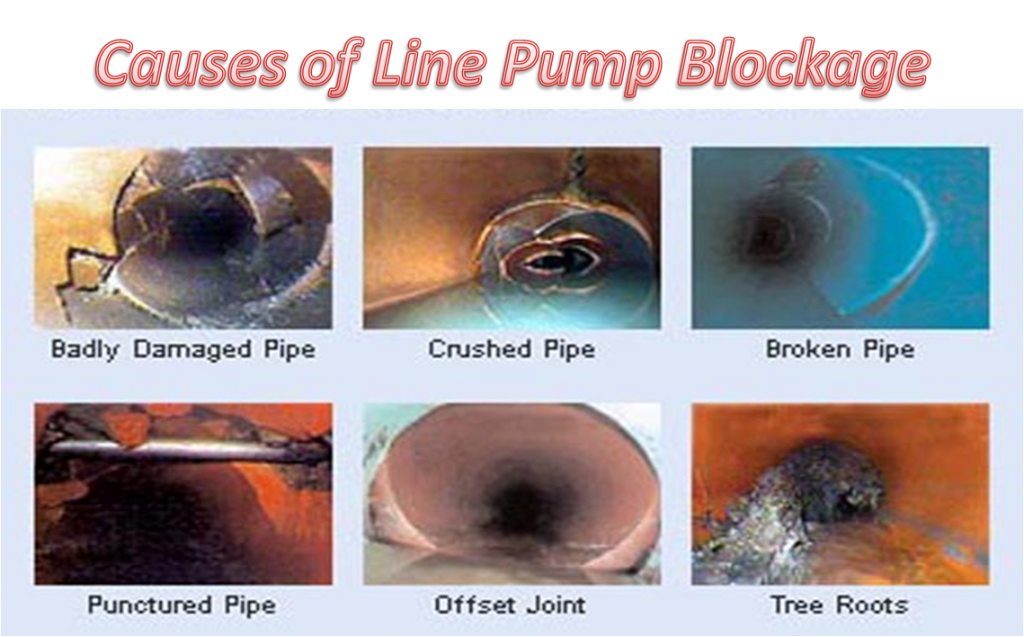

Problem with the Pipeline Itself

The whole concrete pumping process is based on pipeline, because through the pipe concrete has to be passed out. So, it must be based on need of the job. Motor horsepower, pipe length, pumping capacity, etc should match to the job which has to be performed using this pipe.

Pipe cleaning is also a most important factor of the pipeline blockage. If pipe is not cleaned properly then it might create blockage issue. Defective couplings, bad gaskets, etc can also cause problem in concrete pouring. Diameter and air pressure of the pipe is also an important factor to look over. You must take care of all these before starting concrete pouring.

Cause #3:

Operator or Human Error

When there is no error in pipeline or mixture then the error indicated is humane error. It is the most common and expected error of concrete pouring and pipeline blockage if the operator is inexperienced. An operator must have well knowledge about all settings of pipeline. Air pressure, pipe hose settings differs according to the job and mixture. If operator does not well know about this then pipeline will be blocked while concrete pouring. Careless handling of pipe hoses and diameter might also cause pipe blockage.

How to Avoid Blockage

If you will be careful while pumping then you might locate blockage easily. Always check hoses and pipe before starting pumping. All joints of pipe should be checked for leakage. Operator must be well expert in this field.

Important Tips for Clearing Blockage

Never use compressed air to clear the pipe. The compressed air won’t be able to clear the blockage. Use safety precautions to clear the blockage.

To know more about blockage clearing or avoiding tips you may contact us at:

Here, experts of Maple Concrete Pumping, a best concrete pumping company is available to suggest you the best concrete line pumping tips and equipments.